Carbide grades for metal cutting

All of our carbide grades were produced with best metallurgic basic for high premium precision and cutting tools. We like to provide you the optimal choice for your application. Please also profit of our competent team of experts to choose the perfect grade.

Our carbide grades for precision and cutting tools

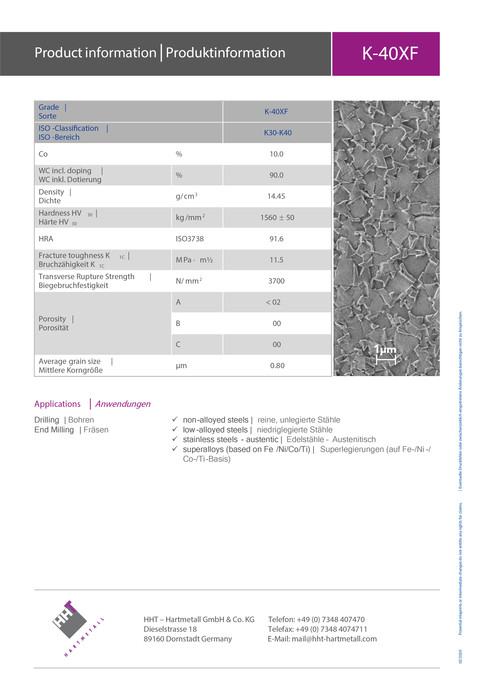

K-40XF - The super ductile one

| ISO-Class. | K30-K40 | |

| Co | % | 10,0 |

| WC incl. doping | % | 90,0 |

| Density | g/cm³ | 14,45 |

| HV30 | kg/mm² | 1560 ±50 |

| HRA | ISO 3738 | 91,6 |

| K1C | MNm | 11,5 |

| Bending strength | N/mm² | 3700 |

| Porosity A | <02 | |

| Porosity B | 00 | |

| Porosity C | 00 | |

| WC-grain size | µm | 0,8 |

|

Fields of applications: Particularly suitable for tough work piece materials in the hardness range <45 HRC, e.g. stainless steels, carbon steels, titanium and nickel alloys. Applicable for low cutting speeds, high feed rates and interrupted cutting. |

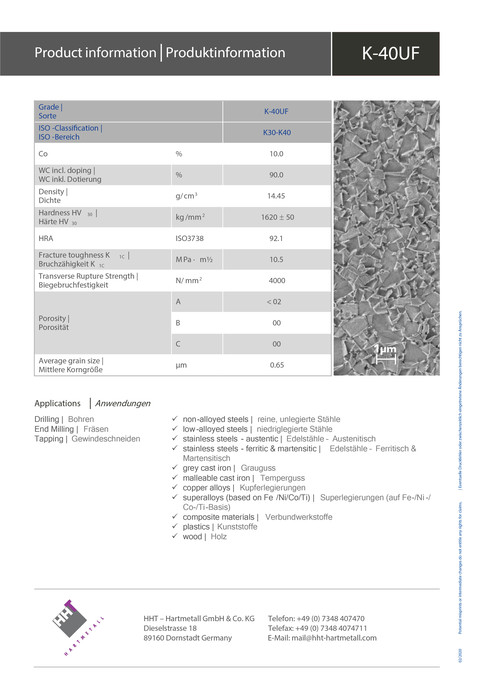

K-40UF - The all-rounder

| ISO-Class. | K30-K40 | |

| Co | % | 10,0 |

| WC incl. doping | % | 90,0 |

| Density | g/cm³ | 14,45 |

| HV30 | kg/mm² | 1620 ±50 |

| HRA | ISO 3738 | 92,1 |

| K1C | MNm | 10,5 |

| Bending strength | N/mm² | 4000 |

| Porosity A | <02 | |

| Porosity B | 00 | |

| Porosity C | 00 | |

| WC-grain size | µm | 0,65 |

|

Fields of applications: Hard an tough, his is our all-purpose grade suitable for titanium and heat-resistant alloys, austenitic stainless steel and grey cast iron.

|

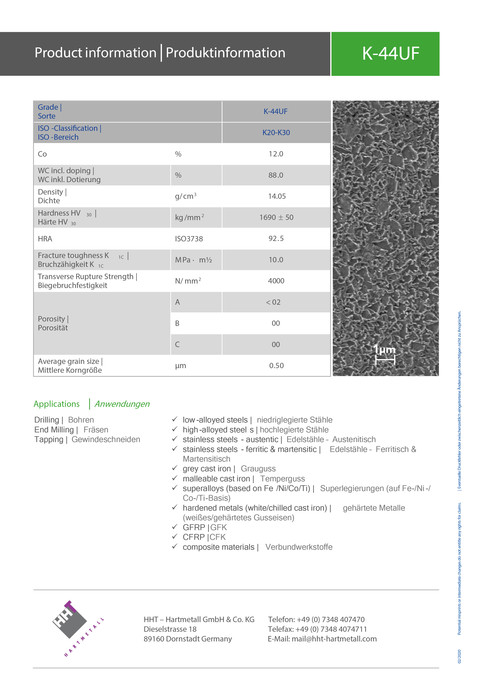

K-44UF - The innovative one

| ISO-Class. | K20-K30 | |

| Co | % | 12,0 |

| WC incl. doping | % | 88,0 |

| Density | g/cm³ | 14,05 |

| HV30 | kg/mm² | 1690 ±50 |

| HRA | ISO 3738 | 92,5 |

| K1C | MNm | 10,0 |

| Bending strength | N/mm² | 4000 |

| Porosity A | <02 | |

| Porosity B | 00 | |

| Porosity C | 00 | |

| WC-grain size | µm | 0,5 |

|

Fields of applications: Especially suitable for titanium- and nickel based alloys, high alloyed steels, grey cast iron and composite materials. For high speed cutting.

|

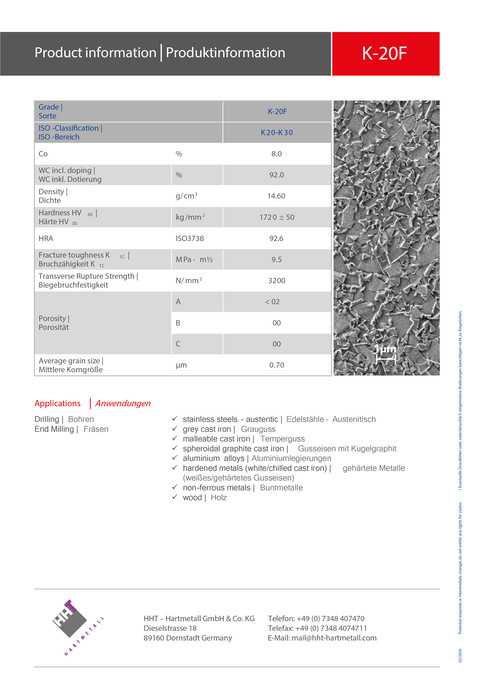

K-20F - The well-tried one

| ISO-Class. | K20-K30 | |

| Co | % | 8,0 |

| WC incl. doping | % | 92,0 |

| Density | g/cm³ | 14,60 |

| HV30 | kg/mm² | 1720 ±50 |

| HRA | ISO 3738 | 92,6 |

| K1C | MNm | 9,5 |

| Bending strength | N/mm² | 3200 |

| Porosity A | <02 | |

| Porosity B | 00 | |

| Porosity C | 00 | |

| WC-grain size | µm | 0,7 |

|

Fields of applications: Wide range for solid carbide tools e.g. grey cast and chilled cast iron, hardened steels and aluminium alloys. |

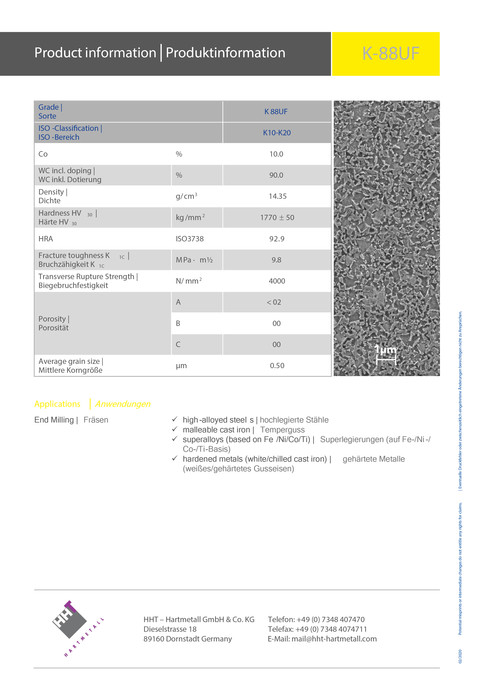

K-40eco - High Performance on lowest PCF level

| ISO-Class. | K10-K20 | |

| Co | % | 10,0 |

| WC incl. doping | % | 90,0 |

| Density | g/cm³ | 14,35 |

| HV30 | kg/mm² | 1770 ±50 |

| HRA | ISO 3738 | 92,9 |

| K1C | MNm | 9,8 |

| Bending strength | N/mm² | 4000 |

| Porosity A | <02 | |

| Porosity B | 00 | |

| Porosity C | 00 | |

| WC-grain size | µm | 0,5 |

|

Fields of applications: For high speed end-milling of hard materials - 45-70HRC - e.g. hardened steels, cast materials and tempered alloys.

|

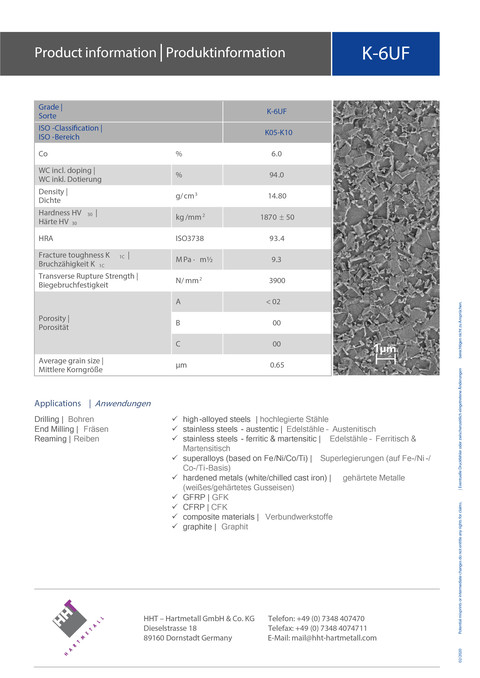

K-6UF - The hard one

| ISO-Class. | K05-K10 | |

| Co | % | 6,0 |

| WC incl. doping | % | 94,0 |

| Density | g/cm³ | 14,80 |

| HV30 | kg/mm² | 1870 ±50 |

| HRA | ISO 3738 | 93,4 |

| K1C | MNm | 9,3 |

| Bending strength | N/mm² | 3900 |

| Porosity A | <02 | |

| Porosity B | 00 | |

| Porosity C | 00 | |

| WC-grain size | µm | 0,65 |

|

Fields of applications: Premium carbide grade for special applications like composite materials (e.g. CFRP), graphite, hardened steels and grey cast iron. |

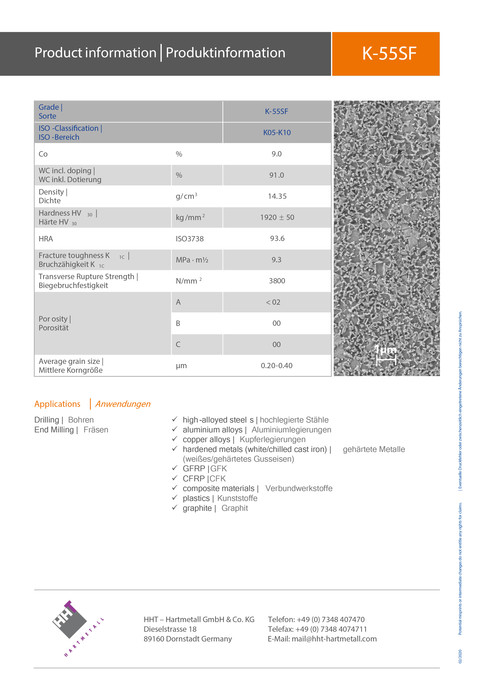

K-55SF - The super-fine one

| ISO-Class. | K05-K10 | |

| Co | % | 9,0 |

| WC incl. doping | % | 91,0 |

| Density | g/cm³ | 14,35 |

| HV30 | kg/mm² | 1920 ±50 |

| HRA | ISO 3738 | 93,6 |

| K1C | MNm | 9,3 |

| Bending strength | N/mm² | 3800 |

| Porosity A | <02 | |

| Porosity B | 00 | |

| Porosity C | 00 | |

| WC-grain size | µm | 0,2-0,4 |

|

Fields of applications: For highly wear-resistant materials, e.g. hardened steels, graphite, aluminium alloys and composite materials like Kevlar and CFRP. For high speed cutting and dry cutting.

|

Do you have further questions?

Please write a mail or call our team!